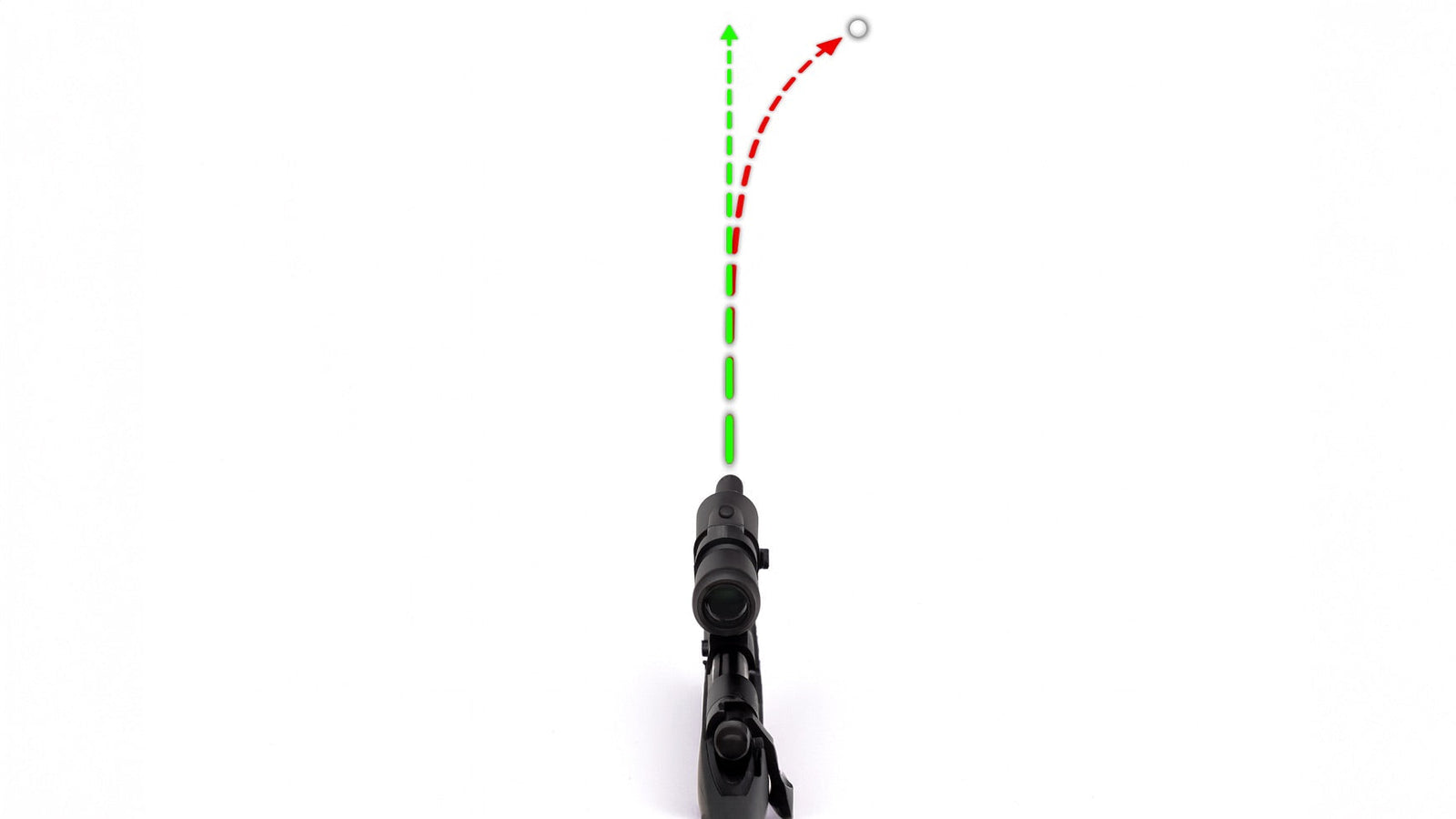

How to Fix BB Curving Issue

Curving BB's on an airsoft replica is probably one of the most annoying things that can occur, especially for bolt-action sniper replicas. Thankfully, there is usually a simple explanation for the curving problem but it can be tricky to find the right problem area as there can be numerous things at play.

We've compiled a list of possible issues that can be causing this sorted from most common to least common. While our expertise comes from primarily teching on airsoft sniper replicas, almost all of these fixes also apply to AEG / GBB replicas.

#1 - Misaligned Scope

Likelihood: Very common

Your scope is your aiming guide, but even a slightly misaligned scope can cause your BBs to seemingly curve. When a scope is off-center, it forces you to tilt your rifle, making it seem like BBs aren’t flying correctly, while in fact that’s just due to the scope misalignment.

How to Fix It

-

Align your scope: Use a small bubble level to ensure your rifle is perfectly level. Then, adjust your scope until it matches the rifle’s alignment.

-

Use a scope alignment kit: These alignment kits, which often include a rail-mounted alignment block and right-angle tool, make precise adjustments simple. While it might not be the most accurate, it will easily get you 95% of the way.

-

Check regularly: Over time, bumps and handling can knock your scope out of alignment. Include alignment checks in your maintenance routine.

You can also check out 5 Tips on How To setup Scope and Airsoft Rifle for More Accuracy from Novritsch for a visual explainer on how to set up a scope and properly zero it in.

#2 - Worn-Out or Dirty Hop-Up Bucking

Likelihood: very common

The hop-up bucking is a soft rubber piece responsible for creating backspin on your BBs, stabilizing their flight path. When this piece is worn, dirty, or old, the backspin becomes inconsistent, leading to curving shots. Even a small dab of silicone can on the contact surface can make your gun shoot inconsistent.

How to Fix It

-

Inspect for wear: Remove the bucking and check for cracks, tears, or signs of aging. If it looks worn, replace it with a new one.

-

Clean it thoroughly: Wash the bucking with warm water and a mild soap to remove dirt and debris. Allow it to dry completely before reassembly.

-

Upgrade to silicone bucking: Unlike traditional rubber buckings, silicone options perform consistently even in varying temperatures, ensuring more reliable backspin.

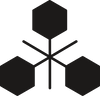

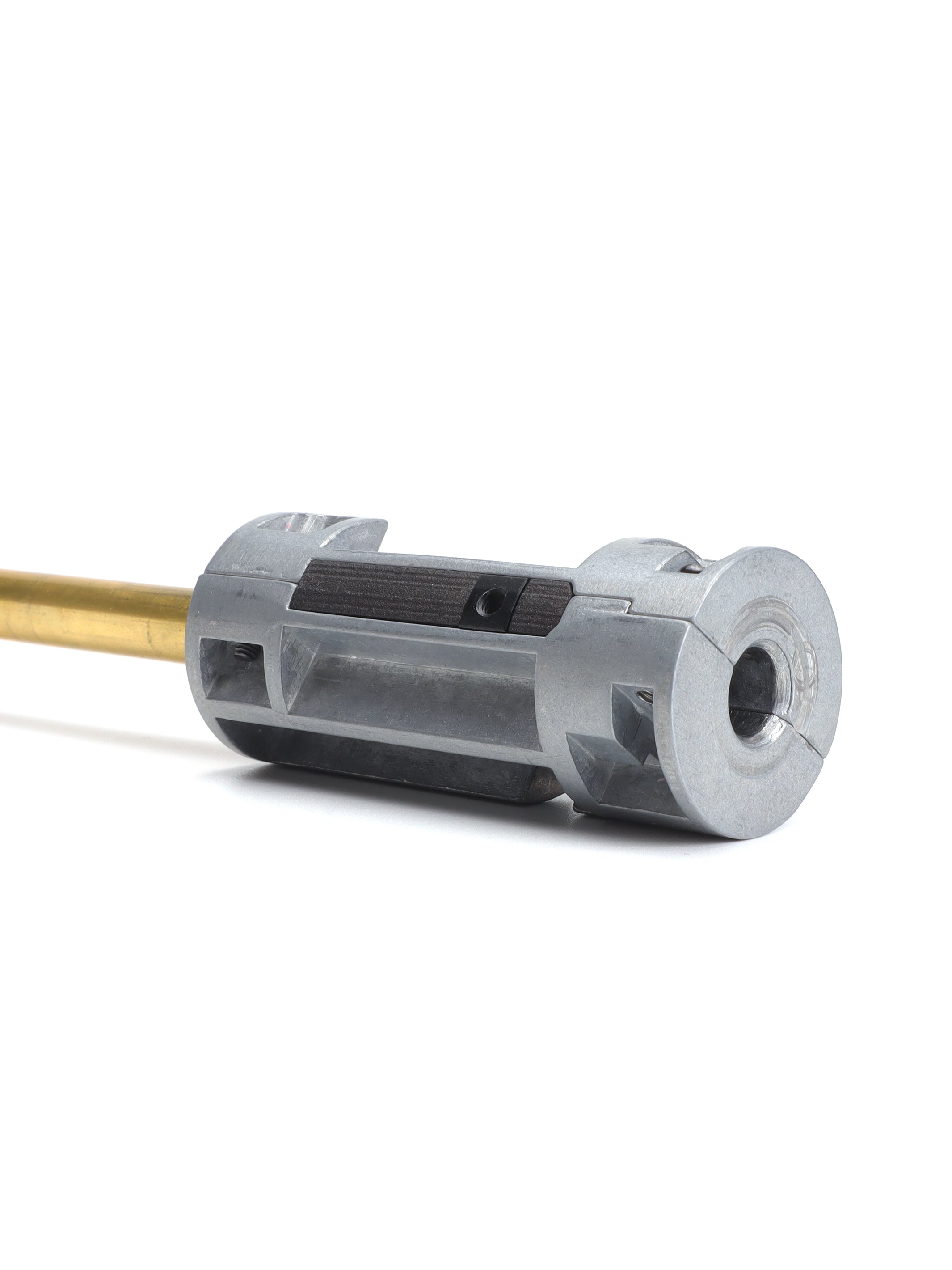

#3 - Improperly Seated Hop-Up Bucking

Likelihood: Pretty common

Sometimes, the hop-up bucking isn’t installed correctly. Misalignment or twisting during assembly can cause uneven pressure on the BB, leading to curved shots. This issue can also occur if the bucking is incompatible with your inner barrel.

How to Fix It

-

Check the seating: Make sure the bucking is aligned correctly with the hop-up unit and inner barrel.

-

Reassemble carefully: If you suspect misalignment, disassemble the hop-up chamber and reassemble it slowly and deliberately. Avoid twisting motions during assembly.

-

Verify compatibility: Ensure the hop cutout on the inner barrel matches the bucking. Misalignment here can cause consistent curving.

#4 - Bent or Damaged Inner Barrel

Likelihood: Pretty common

A bent or improperly taken care of barrel can disrupt the BB’s trajectory as it travels through it. That said, a slight bend in the barrel is very unlikely to cause curving issues - usually even a small scratch in the barrel or debris will have a bigger effect on curving.

How to Fix It

-

Inspect for damage:

-

Check if the barrel is clean from dust, sand, and other types of dirt.

-

Remove the barrel and check for visible bends and warping. Rolling it on a flat surface can reveal subtle irregularities. Slight bend is acceptable - 80% of inner barrels are not straight but they shoot just fine.

-

Replace if needed: If the barrel is slightly bent, most likely it won’t affect shooting trajectory, and all you need to do is properly clean it. However, if it’s considerably bent, consider upgrading to a precision inner barrel for better long-term accuracy.

-

Inspect inner surfaces: Once cleaned, inspect inner barrel surfaces by looking against a bright white surface. Good quality inner barrel will have almost mirror-like surface finish with no scratches. If you see lots of scratches, rought surface finish, it might be time to change out the inner barrel.

#5 - Misaligned Hop-Up Chamber and Inner Barrel

Likelihood: Pretty common

If the hop-up chamber isn’t correctly aligned with the inner barrel, it can also shift the bucking or make it push more on one side of the BB. This issue often arises from improper assembly or sometimes even self-made modifications.

How to Fix It

-

Check Alignment: Disassemble the hop-up unit and carefully inspect how it aligns with the inner barrel. Make sure the barrel sits flush and centered within the unit. When reassembling, avoid applying any twisting force to the inner barrel or bucking, as this can cause misalignment or damage.

-

Inspect for Compatibility: Verify that all components are designed to work together. Inner barrels can vary across platforms, and it’s common to mistakenly use an incompatible one. Ensure the inner barrel you’re using has the correct alignment notches for your specific hop-up unit.

-

Secure the Fit: Once everything is aligned and compatible, use screws to firmly secure the hop-up chamber. This prevents any shifting or movement during gameplay, which could affect performance.

#6 - BBs hitting endcap/suppressor

Likelihood: Not common

A common issue is BBs making contact with the endcap of the outer barrel or a misaligned suppressor. This usually happens when the suppressor or muzzle isn’t centered with the inner barrel, causing the BB to get caught on the edge as it exits. This kind of interference can drastically alter the BB’s trajectory, often causing unpredictable curving or loss of range.

How to Fix It

-

Check your replica:

-

Fire the replica without any muzzle devices to see if the issue disappears. If the BBs fly straight, you’ve found your problem.

-

Look closely at the endcap or the inside lip of the suppressor. If you notice a visible buildup of BB residue or scuff marks, especially concentrated in one specific spot, it’s a strong indicator that BBs are clipping that area during firing. Remove the suppressor or muzzle device and inspect whether it screws on straight. If it wobbles or sits off-center, it’s likely the cause.

-

Re-center or replace: Realign the suppressor, or in some cases, you may need to replace a warped or poorly designed muzzle attachment entirely.

Regularly checking your muzzle area for residue or damage can help you catch this issue before it affects performance during a game.

#7 - Uneven Pressure on the Hop-Up Bucking

Likelihood: Not common

Uneven pressure on the hop-up bucking can drastically affect your BB's trajectory and accuracy. This imbalance typically happens when the nub or arm inside the hop-up unit applies inconsistent force on the bucking, causing one side to exert more pressure than the other. The result is irregular backspin and a noticeable curve in the BB's flight path.

How to Fix It

-

Inspect the nub and arm: Disassemble the hop-up unit and ensure that the nub is properly seated and positioned to apply even pressure. This can be a pretty commoon issue on GBB pistols that use a bent metal piece as an arm.

-

Test the bucking alignment: Check the bucking to confirm it is evenly placed around the inner barrel. Misaligned buckings may cause uneven spin.

-

Upgrade for precision: Consider upgrading to a high-quality nub or a flat hop system, which provides more consistent pressure and better overall performance.

#8 - Faulty rail mounting threads

Likelihood: Very rare

In a few rare cases, there might be a manufacturing defect on your replica where the rail mounting holes are off-axis, therefore causing the rail to sit at an angle. So even if you level the scope properly against the rail, it would still be skewed to one side. While this is an extremely rare cause, we have seen it happen.

How to Fix It

-

Level scope against hop up chamber: Try to align the scope visually first by looking at the vertical reticle line to align roughly with the replica and then make micro adjustments while doing test shots until your gun is shooting straight.

-

Replace receiver / submit warranty claim: If you can verify that the threads indeed are the issue, reach out to your replica manufacturer and ask for a replacement part. Don’t forget to submit clear evidence showing the issue.

General Maintenance Tips for Accuracy

While addressing specific causes can fix curving BBs, maintaining overall rifle health is key to long-term performance. Keep these tips in mind to maintain accuracy and avoid common issues.

→ Clean Regularly

Residue and debris can easily accumulate in your barrel and hop-up system. Use a cleaning rod and paper towel (we like to also use a little bit of rubbing alcohol) to clean the inner barrel before every skirmish.

→ Check Tightness

Over time, screws and components can loosen due to vibrations. Regularly inspect your rifle to ensure all parts are secure, particularly the scope mount screws, rifle stock screws, and outer barrel assembly. Make sure that they’re not overtightened as well.

→ Use Quality BBs

Low-quality BBs may have inconsistent weight or unsmooth surfaces or residue left over from manufacturing, which can cause unpredictable flight paths or even cause jams. Invest in high-quality, polished BBs for consistent performance.

→ Test After Adjustments

Whenever you make changes or perform maintenance, take your rifle to the test range. A few trial shots will help you verify that everything is functioning as expected.

Do you know of any other possible scenarious that have been causing curving on your replica? Let us know in the comments section and we'll be updating the article to keep it most up to date.

Happy shooting, and may your BBs fly straight and true!

Leave a comment